Unlocking Industrial Excellence: A Comprehensive Guide to the Best Camlock Couplings

The industry world revolves around connections, and at the heart of these connections lie vital components such as camlock couplings. This article provides a comprehensive overview of camlock collars, including their significance, applications, and tips for choosing the best ones.

Understanding Camlock Couplings

Camlock couplings, commonly referred to as cam and groove couplings, are extensively utilized in various industries for transferring liquids and bulk materials. These couplings are designed for quick and easy connection and disconnection of hose pipes, allowing for efficient operations. They are an essential tool in sectors such as chemical processing, oil and gas, food and beverage, and more.

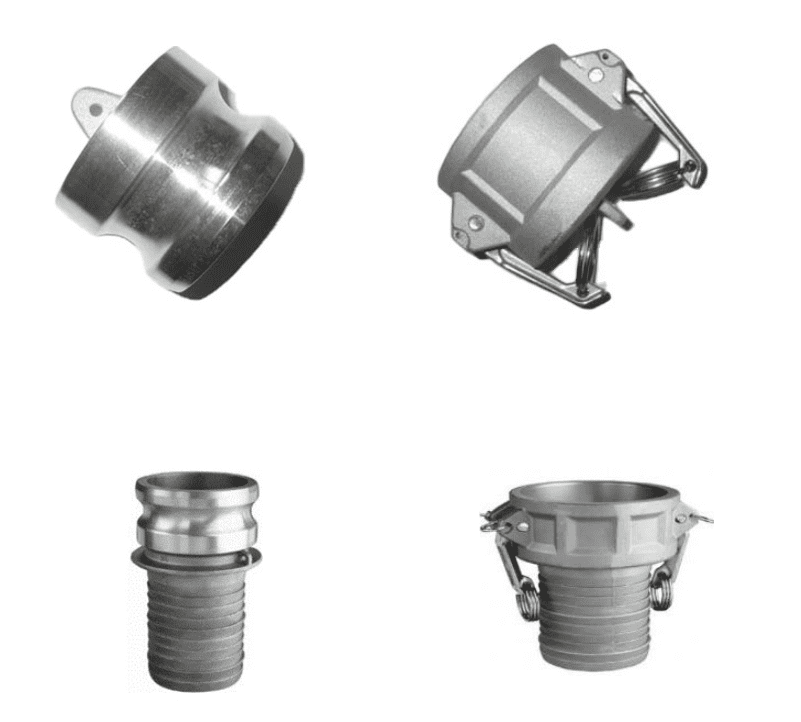

The design of a camlock coupling includes a male (plug) and a female (coupler) end. The male end is inserted into the female end, and the coupler cam arms are closed to secure the connection. This results in a tight seal that prevents leakage, making camlock couplings a reliable and efficient choice for many industrial applications.

The Importance of Choosing the Right Camlock Coupling

The right camlock coupling can make a significant difference in industrial operations. A high-quality collar ensures a secure and leak-free connection, enhancing operational efficiency and minimizing the risk of accidents due to leaks or spills.

On the other hand, a poor-quality camlock coupling might not provide a secure seal, leading to leaks, equipment damage, and potential workplace hazards. Hence, the collar’s quality directly affects your operations’ performance, making it imperative to choose the best camlock coupling.

Exploring the Best Camlock Couplings on the Market

Regarding quality and reliability, some brands have set the standard in the industry. Here are some of the top camlock coupling brands on the market:

- Brand A: Known for its high-quality materials and precision engineering, it offers a range of camlock couplings built to last and perform excellently under various conditions.

- Brand B: Brand B camlock couplings are appreciated for their innovative design that ensures easy installation and disconnection, enhancing operational efficiency.

- Brand C: If durability and strength are your primary concerns, Brand C is a go-to choice. Their couplings are designed to withstand high pressure and harsh conditions, making them ideal for heavy-duty applications.

These brands have been chosen based on their product quality, customer reviews, and industry reputation. Each offers a range of products, allowing you to choose the best camlock coupling based on your specific requirements.

A Deep Dive into the Specifications of Camlock Couplings

Understanding the specifications of Camlock couplings can help you make an informed decision. Here are some crucial aspects to consider:

Materials

Camlock couplings are made from various materials, each offering different properties. Some common materials include:

- Stainless Steel: Stainless steel camlock couplings are renowned for their strong and corrosion-resistant properties, making them ideal for various applications. They are particularly useful in situations where hygiene and durability are crucial.

- Aluminum: Aluminum couplings are lightweight, making them suitable for applications where weight is a concern. They also offer decent corrosion resistance.

- Brass: Brass couplings provide good corrosion resistance and are ideal for water, oil, and gas applications.

- Polypropylene: For applications involving chemicals, polypropylene camlock couplings, with their excellent chemical resistance, can be a good choice.

Sizes

Camlock couplings are available in various sizes, typically 1/2 inch to 6 inches. The measure needed would depend on the hose or pipe you’re working with and the flow rate required.

Types

Different camlock couplings – Type A, B, C, D, E, F, DC, and DP – are designed for specific connection requirements. For example, Type A is a male adapter with a female thread, while Type B is a female coupler with a male thread. Your choice of type would depend on the connection requirements in your application.

Pressure Ratings

The pressure rating indicates the maximum pressure that the camlock coupling can withstand. Choosing a collar with a pressure rating that meets or exceeds the stress in your application is essential to ensure safety and reliability.

In conclusion, understanding camlock couplings, their importance, and the specifics of choosing the right one is crucial for industrial efficiency. Equipped with this knowledge, you can confidently explore the best camlock couplings on the market, ensuring you choose the one that meets your specific operational needs.

The Pros and Cons of the Best Camlock Couplings

Having explored the top brands in the camlock coupling market, it’s crucial to delve deeper into these products’ advantages and disadvantages. By understanding these aspects, you’ll be better equipped to make an informed decision tailored to your requirements.

Brand A

- Pros: Noted for their excellent build quality, Brand A’s camlock couplings are praised for their long lifespan and durability. Their high-precision engineering ensures secure seals and efficient performance.

- Cons: The primary downside to Brand A is cost. Their high-quality products come with a relatively high price tag, which may only suit some budgets.

Brand B

- Pros: Brand B’s main strength lies in the innovative design of their camlock couplings, allowing for quick and easy installation and disconnection. Their products can significantly enhance workflow efficiency.

- Cons: While their designs are innovative, they might not be as durable as some other brands when subjected to extremely harsh conditions.

Brand C

- Pros: Brand C’s camlock couplings stand out for heavy-duty industrial applications. They are known for their exceptional strength and ability to withstand high pressure and harsh environments.

- Cons: The trade-off for such durability and strength is weight. Brand C’s products tend to be heavier than comparable couplings, which might be a concern in applications where weight is a critical factor.

A Comprehensive Buying Guide for Camlock Couplings

With the knowledge of camlock couplings, their importance, and the best ones available in the market, you are now ready to purchase the best camlock coupling for your needs. Here’s a step-by-step guide to help you navigate your buying process:

Identify Your Requirements

Understand your specific requirements, including the material, size, and type of coupling you need. Also, consider the conditions under which the collar will be used, such as pressure, temperature, and fluid transfer type.

Choose the Right Material

Select the most suitable material for your coupling based on your operational requirements and the nature of the fluids you’re dealing with. This could range from stainless steel for high strength and durability, aluminum for lightweight applications, brass for good corrosion resistance, or polypropylene for excellent chemical resistance.

Select the Correct Size and Type

Choose a coupling size that matches your hose or pipe size and meets your flow rate requirements. Choosing the correct type of camlock coupling (A, B, C, D, E, F, DC, DP) that matches your specific connection needs is crucial.

Check Pressure Ratings

Ensure that the coupling’s pressure rating is suitable for your application. A good rule of thumb is to choose a coupling with a pressure rating that exceeds the maximum pressure in your system.

Consider Brand Reputation and Reviews

Finally, consider the reputation of the brand and the reviews of its products. High-quality brands with good reviews are often a reliable choice. Also, consider the post-purchase support they offer, such as warranties and customer service.

Maintenance and Care for Camlock Couplings

Proper maintenance of your camlock couplings is vital for ensuring their longevity and optimal performance. Here are some maintenance and care tips:

Regular Cleaning

Clean your camlock couplings regularly to prevent the buildup of dirt and debris, which could affect their sealing capability and overall performance.

Periodic Inspection

Regularly inspect the couplings for signs of wear and tear. Check for damage such as cracks, corrosion, or a worn-out seal. Replace any damaged parts promptly to prevent leakage and potential accidents.

Lubrication

Camlock couplings, especially those made of metal, should be periodically lubricated to ensure smooth operation and to prevent rust and corrosion.

Proper Handling and Storage

Handle the couplings with care during installation and disconnection to prevent damage. Store them in a dry and clean place to avoid corrosion and degradation when not in use.

Understanding the Future of Camlock Couplings

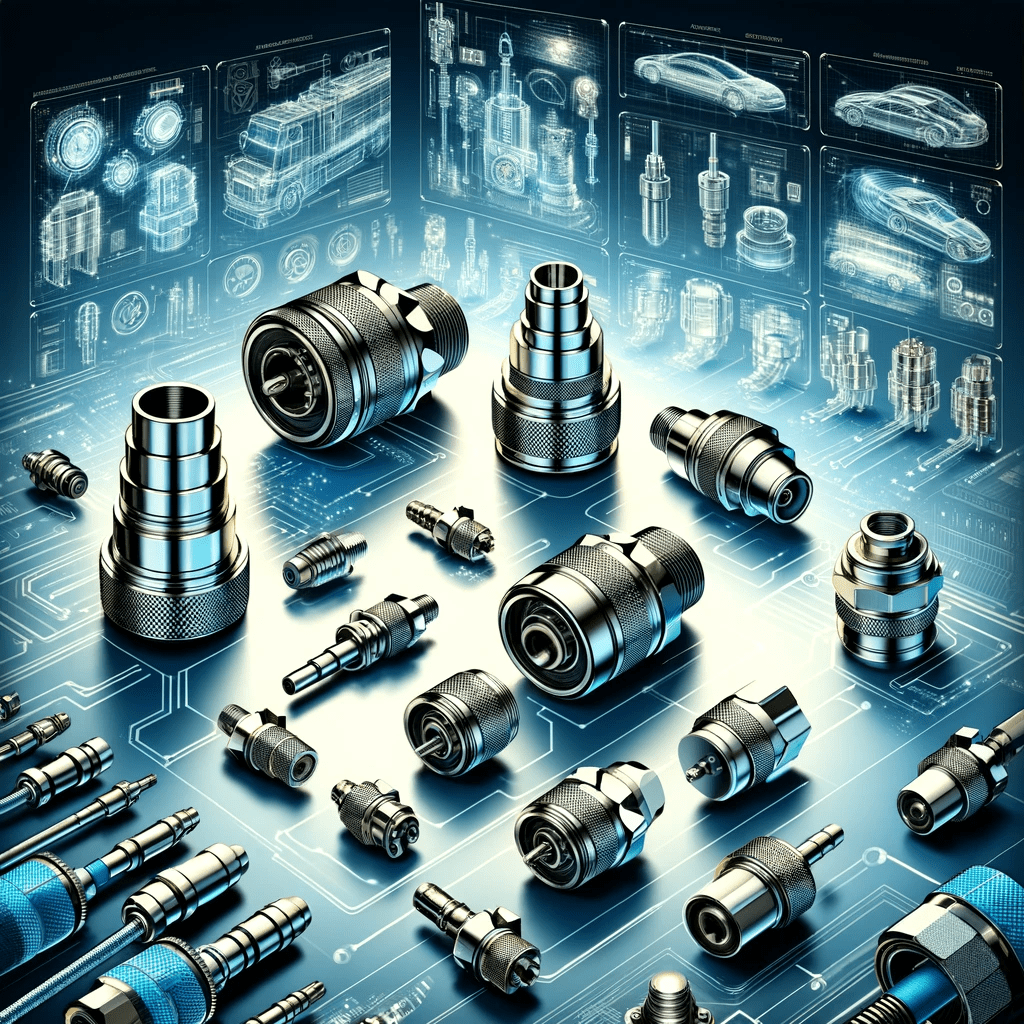

As technology advances, so do the design and capabilities of Camlock couplings. Future trends in this industry are expected to be driven by innovations in material science and design engineering.

We may see couplings made from advanced materials offering superior strength, durability, and corrosion resistance. The future may also bring us smart camlock couplings equipped with sensors to monitor pressure, temperature, and flow rate, enabling predictive maintenance and enhancing operational efficiency.

By staying updated with these technological advancements, you can ensure that you continue to choose the best camlock couplings for your needs, even as those needs evolve with time.

Camlock couplings are critical in various industries, ensuring secure and efficient fluid and material transfer connections. Understanding what they are, their significance, and how to choose the best ones is crucial for any industry professional. This guide has armed you with this knowledge and more, providing the tools to make an informed choice when selecting the best camlock couplings for your needs. Now, you’re ready to make a wise purchasing decision and equipped to maintain your collars properly and stay ahead of future trends in this essential industry.