Top Factors to Consider When Choosing a Quality Camlock Coupling

Camlock couplings, a linchpin in fluid transfer operations, need careful selection to ensure operational excellence. This guide takes you through the integral aspects of these devices, from their fascinating history to the significance of material choice.

Brief History of Camlock Couplings

Before diving into the intricacies of selecting a camlock coupling, understanding its historical evolution offers a unique perspective on its importance.

The Dawn of Quick Connects

Emerging in the mid-20th century, camlock couplings provided industries with a swift, leak-proof method to connect hoses and pipes. These couplings rapidly became popular in the military, where fuel lines’ quick connection and disconnection were crucial.

From Military to Industries

Post their military debut, camlock couplings found favor in numerous industrial applications – from food and beverage production to petroleum industries. Their ease of use and reliability propelled them to be an industry favorite.

Key Milestones:

- 1950s: Introduction in the military for fuel transfers.

- 1970s: Broad industrial adoption, notably in petrochemical sectors.

- 2000s: Innovations in materials and design, enhancing safety and efficiency.

Understanding the Basics: What is a Camlock Coupling?

At its core, a camlock coupling is a type of fitting that allows for quick, secure connection and disconnection of fluid transfer lines without needing tools. Let’s dissect its mechanics.

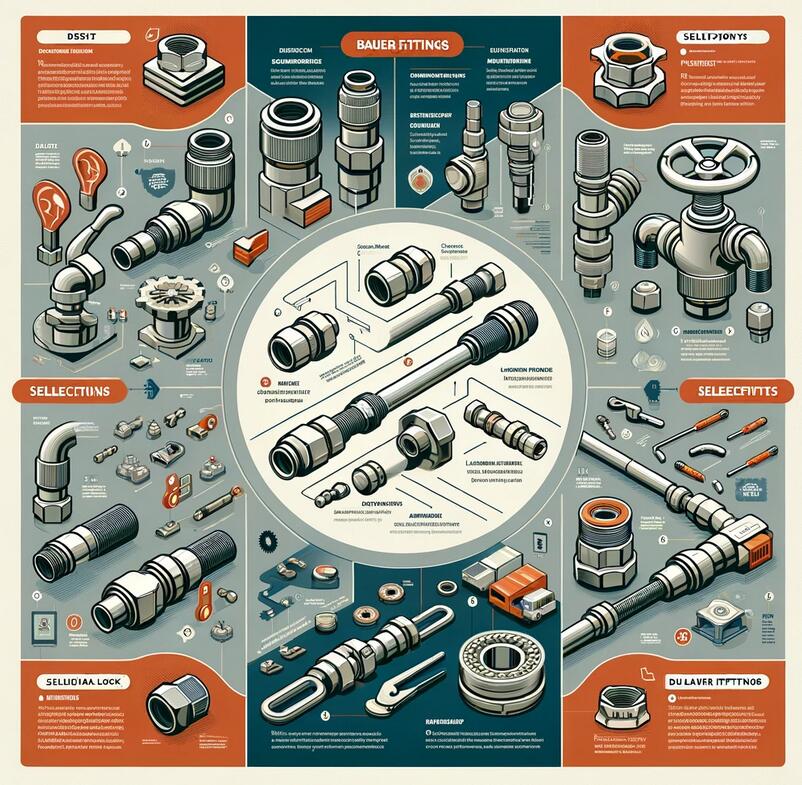

Components of a Camlock Coupling

**

The anatomy of a camlock coupling is fascinating. Key components include:

- Coupler (the female end).

- Adapter (the male end).

- Cam arms, ensuring a tight seal.

- Gasket, preventing leaks.

How Does It Work?

The user slides the adapter into the coupler and presses the cam arms down. This simple action creates a secure, leak-proof connection. Its tool-free nature revolutionized fluid transfers, cutting downtime dramatically.

Types of Camlock Couplings: An Overview

Ranging from Type A to Type F, each camlock coupling variant serves specific needs. For instance, Type A has a male adapter and female thread, while Type B has a female coupler and a male cable. The versatility across types ensures a fit for every requirement.

Materials Matter: Exploring Different Builds

The fabric of a camlock coupling is pivotal. It determines durability, chemical resistance, and the range of temperatures a coupling can handle.

Stainless Steel: The Stalwart

Renowned for its robustness and resistance to corrosion, stainless steel camlock couplings are ideal for high-pressure scenarios and environments with aggressive chemicals. Often used in pharmaceutical and food industries due to their non-contaminant nature.

Aluminum: Lightweight yet Mighty

Boasting a perfect blend of strength and lightness, aluminum camlock couplings cater to industries like petroleum, where weight efficiency matters. They also exhibit decent resistance to corrosion.

Brass: Classic and Efficient

Brass camlock couplings are popular in water supply applications. Their corrosion-resistant properties and excellent conductivity make them a staple in various setups.

Polypropylene and Beyond

For applications that demand resistance to certain solvents and chemicals, polypropylene camlock couplings emerge as the hero. Other materials like nylon also find their niche in specific industrial contexts.

Size and Specifications: Getting the Perfect Fit

Like a mismatched jigsaw puzzle, the wrong camlock coupling size can jeopardize operations. Ensuring the perfect fit is more than a game of dimensions— it &’s about compatibility and efficiency.

Size Matters

Camlock couplings range from 10 to 8 inches, catering to diverse hose and pipe sizes. Whether it’s a massive oil transfer or a minute chemical process, there’s a size tailored for every need.

Accuracy in Specifications

Beyond mere dimensions, factors like pressure ratings, temperature thresholds, and material compatibility come into play. It &’s essential to cross-reference your operational requirements with the camlock coupling &’s specs.

The Pitfalls of Mismatched Sizes

Choosing a camlock coupling that & is too large can lead to ineffective seals and potential leaks. On the flip side, a size too small might not withstand the pressure, leading to operational failures. Hence, precision is paramount.

In the quest for the ideal camlock coupling, historical insights, fundamental understanding, material choice, and precise sizing emerge as critical waypoints. As you journey through the remaining factors, remember that every small detail can significantly impact your operations’ efficiency and safety.

Seals and Gaskets: Ensuring a Leak-Free Experience

Beyond the core structure, a camlock coupling & and integrity largely depend on the quality of its seals and gaskets. These components are pivotal in preventing leaks and ensuring the smooth transfer of fluids.

The Role of Seals

Seals maintain the internal pressure and prevent external contaminants from entering the system. Their placement between the male and female ends of the coupling ensures a tight connection.

Material Choices and Their Implications

- Nitrile: A standard choice for many industries due to its oil-resistant properties.

- EPDM (Ethylene Propylene Diene Monomer): Best for hot water and steam, resisting weathering and chemicals.

- Viton: Known for high-temperature resistance and compatibility with most chemicals.

- PTFE (Polytetrafluoroethylene): Offers superior chemical resistance, especially for aggressive acids and solvents.

Checking Integrity

Over time, gaskets can wear out or get damaged. It’s crucial to inspect and replace them to maintain a leak-free operation regularly. Signs of wear, swelling, or cracking indicate an immediate need for replacement.

Safety Precautions: The Role of Quality in Safety

Quality isn’t just about efficient operations—it’s paramount for safety. Especially in industries where hazardous chemicals or high pressures are involved, the choice of camlock coupling can make a significant difference.

Quality Equals Safety

A high-quality camlock coupling is designed with safety standards in mind. They are built to withstand expected pressures, resist possible chemical reactions, and prevent leakages.

Certifications to Look Out For

Several industry standards ascertain the safety of camlock couplings. ISO 9001, for instance, ensures quality management, while A-A-59326 (MIL-C-27487) is specific to cam and groove couplings’ performance and interchangeability. Always opt for products with recognized certifications.

Environmental and Operational Conditions

The performance and lifespan of a camlock coupling can be greatly affected by the environment in which it is used.

Extreme Temperatures

From cold to scalding hot conditions, the material and design of the camlock coupling should be suited to handle the extremes. For instance, stainless steel and Viton seals might be ideal for high-temperature scenarios.

Chemical Resistance

Whether it &’s a corrosive acid or a simple aqueous solution, the camlock coupling material and seals should resist potential chemical reactions.

Environmental Factors

Factors like UV radiation, humidity, and saltwater can affect the longevity and performance of camlock couplings. Opt for UV-resistant and corrosion-resistant variants when operating in challenging environments.

User Reviews and Brand Reputation

While technical specifications provide a solid foundation, user reviews, and brand reputation offer real-world insights into a product and its performance.

Value of Consumer Feedback

Users often share their experiences, highlighting strengths and pointing out potential issues. These reviews can be invaluable when assessing the reliability and performance of a camlock coupling in real-world conditions.

Recognizing Reputable Brands

Brands with a long-standing history and positive industry reputation are generally more trustworthy. Their products often have guarantees, and they prioritize customer service.

Red Flags in Reviews

While occasional negative reviews are normal, consistent complaints about leaks, material degradation, or poor customer service should serve as warning signs.

Price vs. Value: Making an Informed Investment

While it might be tempting to opt for the most affordable option, it &’s crucial to understand the long-term implications of your choice.

True Cost of Quality

A quality camlock coupling, although pricier initially, can save costs in the long run. Fewer replacements, reduced downtime, and minimized leakages contribute to long-term savings.

The Risk of Cheap Alternatives

Opting for a cheaper, lower-quality camlock coupling might lead to frequent replacements, potential operational hazards, and inefficiencies, eventually costing more than a quality product.

Choosing a camlock coupling goes beyond picking a product off the shelf. It’s about understanding its history, mechanics, material implications, and the importance of safety and environmental considerations. To guarantee a fluid transfer operation that is safe, efficient, and cost-effective, it is necessary to consider both technical specifications and real-world feedback comprehensively. Always prioritize quality— it’s an investment in safety, efficiency, and long-term value.