Mastering Bauer Fittings: A Complete Guide for Optimal Fluid Handling

In the realm of fluid handling and irrigation systems, the efficiency and reliability of the connections play a pivotal role. Bauer fittings, known for their robustness and versatility, stand out as a superior choice for a myriad of applications across industries. This guide aims to illuminate the significance of Bauer fittings, delving into their design, benefits, and practical advice on selection and installation, providing readers with a treasure trove of knowledge to enhance their fluid handling systems.

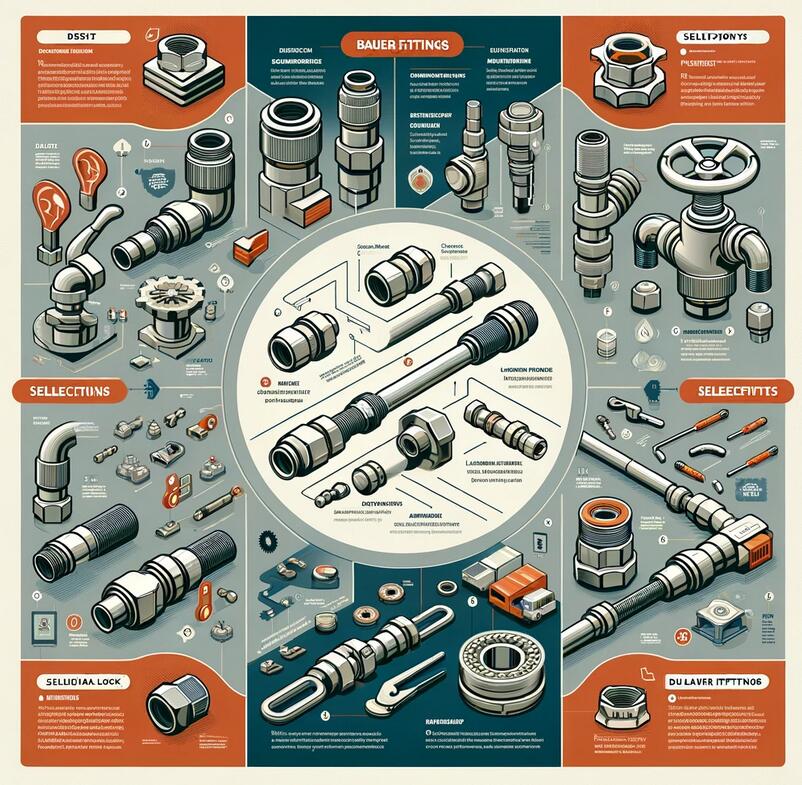

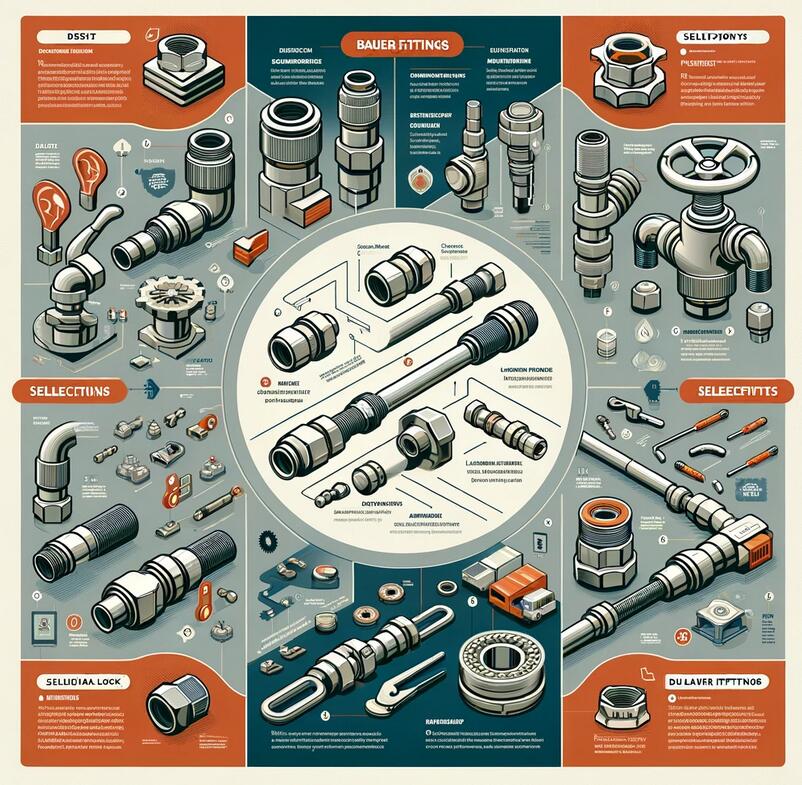

Understanding Bauer Fittings

Bauer fittings, named after their originator, have carved a niche in the fluid handling sector due to their unique design and functionality. These fittings employ a simple yet effective lever lock system that ensures a secure and watertight connection between hoses and pipes, critical for the efficient transport of liquids.

- Definition and History: Originating in the early 20th century, Bauer fittings have evolved from basic agricultural applications to a staple in industries requiring fluid transport, including construction and mining.

- Design and Components: The hallmark of Bauer fittings is their ball and socket design, complemented by a lever lock mechanism. This design facilitates quick assembly and disassembly, ensuring a tight seal and resistance to leaks.

- Types and Applications: From galvanized steel to stainless steel variants, Bauer fittings come in various sizes and materials, each suited to specific pressures and environments. Their versatility makes them indispensable in sectors ranging from firefighting to wastewater management.

The Benefits of Using Bauer Fittings

The adoption of Bauer fittings across diverse industries is no coincidence. Their benefits are manifold, contributing significantly to their popularity.

- Durability: Crafted to withstand harsh conditions, Bauer fittings are known for their longevity, offering resistance against corrosion, abrasion, and UV radiation.

- Easy Installation: The simplicity of the lever lock system allows for quick connection and disconnection, saving valuable time and reducing labor costs.

- Versatility: Bauer fittings’ adaptability to various situations makes them a go-to choice for fluid handling needs, compatible with a wide range of liquids and used in numerous applications.

Selecting the Right Bauer Fitting for Your Needs

Choosing the appropriate Bauer fitting is crucial for ensuring system efficiency and longevity. Several factors come into play when selecting the right fitting.

- Size and Material: Consider the diameter and material of the fittings based on the type of liquid and the system’s pressure requirements. For example, stainless steel is preferred for corrosive environments, while galvanized steel is suitable for less aggressive conditions.

- Pressure Rating: Ensure the fitting can withstand the system’s maximum pressure. This is vital to prevent leaks or fitting failures under stress.

- Application Specifics: Different applications may require specific fitting types. For instance, certain Bauer fittings are designed for suction, while others are better suited for discharge.

Utilizing real-world case studies can further illustrate the critical nature of proper fitting selection. For instance, in agricultural irrigation systems, choosing the right Bauer fitting size and material can significantly impact water efficiency and crop yield.

Installation Tips and Best Practices

Correct installation of Bauer fittings is paramount to the success of any fluid handling system. Here are some tips and best practices to ensure optimal installation:

- Preparation: Before installation, ensure all components are clean and free from debris. This prevents potential leaks or damage to the fittings.

- Correct Assembly: Follow the manufacturer’s instructions closely when assembling the fittings. Incorrect assembly can lead to leaks or system failure.

- Maintenance: Regular maintenance and inspection of Bauer fittings are crucial for longevity. Check for signs of wear and tear, and replace fittings as needed.

Moreover, familiarizing oneself with common installation mistakes, such as over-tightening or mismatching fitting sizes, can prevent potential issues, ensuring a seamless and efficient fluid handling system.

Innovations and Trends in Bauer Fitting Technology

The landscape of Bauer fittings is continually evolving, with innovations aimed at enhancing performance and user experience. Recent advancements include the development of lightweight, high-strength materials and the integration of smart technologies for monitoring fitting integrity in real-time. Such innovations not only improve the efficiency of fluid handling systems but also pave the way for more sustainable and environmentally friendly solutions.

Conclusion

Bauer fittings play an indispensable role in the efficient management of fluid handling systems across various industries. From their robust design and versatile applications to the ease of installation and maintenance, Bauer fittings offer a reliable solution for ensuring seamless fluid transport. By carefully selecting the right type of fitting and adhering to best installation practices, businesses can significantly enhance the performance and reliability of their systems. As technology advances, the future of Bauer fittings looks promising, with continuous improvements aimed at meeting the evolving needs of industries worldwide.

Whether you are involved in agriculture, construction, mining, or any sector requiring efficient fluid handling, embracing Bauer fittings can lead to marked improvements in system efficiency and reliability. The key lies in understanding the specific requirements of your application and choosing fittings that offer the best compatibility and performance. With this comprehensive guide, we hope to have provided valuable insights into making informed decisions regarding Bauer fittings, contributing to the success of your fluid handling projects.