Male Camlock Fitting

Male Camlock Fittings are a type of quick-connect coupling used in many industrial applications. They provide a secure, leak-proof connection for pipes and hoses with different diameters or materials. Male camlocks are available in a wide variety of sizes, materials and configurations to meet the needs of any application. With their simple design and easy installation process, they offer an efficient solution for connecting two lines quickly and securely without having to use traditional threaded connections. In this article we will discuss the various types, how they can be installed correctly and safely, as well as some common applications where they may be used.

Overview of Male Camlock Fitting

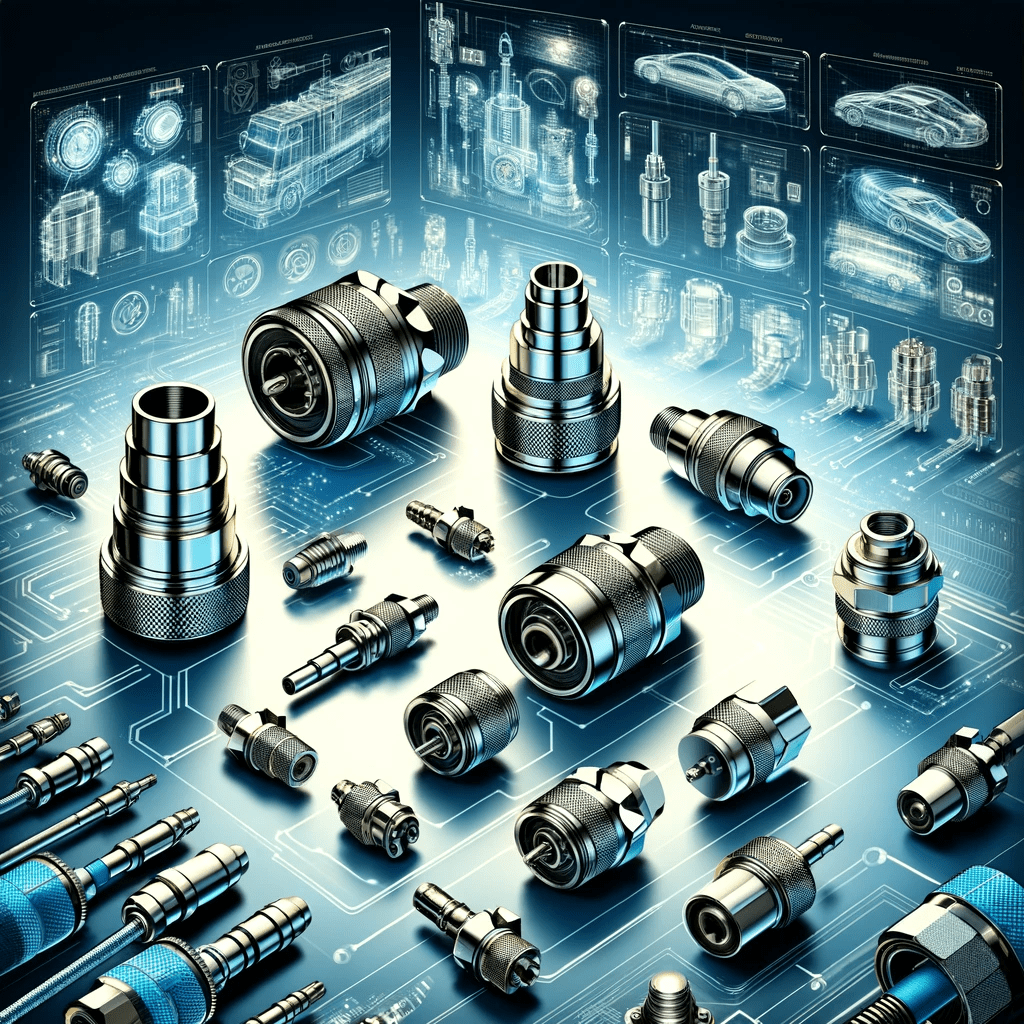

Male camlock fittings are a type of quick-connect coupling that provides an easy and secure connection for pipes and hoses with different diameters or materials. They have a simple design which makes them easy to install without the need for traditional threaded connections. Male camlocks come in many sizes, materials, and configurations, so they can be used to fit any application.

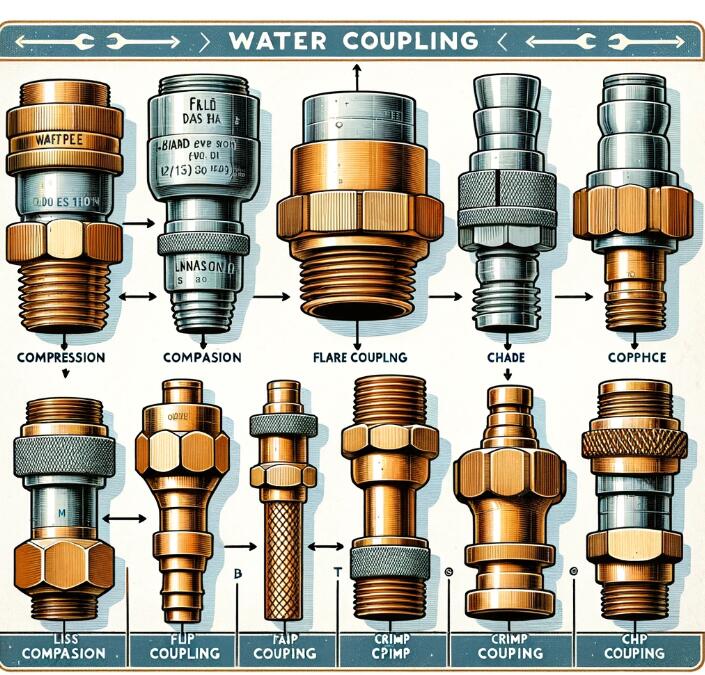

Types of Male Camlock Fittings

Male camlock fittings are available in a variety of sizes, materials, and configurations to meet the needs of any application. The most common types include stainless steel, brass, aluminum, polypropylene and nylon. Each type has its own unique benefits: stainless steel offers superior corrosion resistance; brass is lightweight yet strong; aluminum provides high strength and low weight; polypropylene is highly resistant to chemicals; and nylon is ideal for use with food-grade applications. Depending on the application or environment they will be used in, different types may provide better performance than others.

How to Install a Male Camlock Fitting

1. Ensure that the pipe and fitting surfaces are clean and free from dirt, debris, or any other substance that may interfere with a secure connection.

2. Slide the male camlock into place over the end of the pipe or hose and press firmly in order to secure it in place.

3. Inspect the connection for leaks by conducting a pressure test using water or air at no more than 50 psi (3 bar).

4. If necessary, use thread sealant tape or paste on both threads of mating halves before assembly to ensure a leak-proof fit when making connections between pipes with different materials such as metal and plastic/rubber hoses.

5. Check for proper alignment of all parts before tightening up any bolts and nut fasteners used for securing camlocks together – this will help ensure an even distribution of force around your entire joint area during operation which is important for maintaining long-term performance without leakage issues occurring down the line!

6. Tighten all bolts securely using appropriate tools such as wrenches or ratchets until desired torque is achieved; do not overtighten them otherwise you risk damaging both parts involved due to excessive strain being applied unnecessarily!

7. Double check again once everything is tightened for any loose fittings or other potential issues such as leaks before use.

Maintenance Tips

In order to ensure a secure and long-lasting connection between pipes or hoses, proper maintenance of male camlock fittings is essential. It’s important to inspect the fitting regularly for any signs of wear and tear that could lead to leakage issues down the line. Additionally, regular cleaning and lubricating can help keep your fittings in good condition for longer periods of time. Here are some simple tips on how you can maintain your male camlock fittings properly:

1. It is important to inspect regularly for any signs of wear and tear that could lead to leakage. Check for cracks, chips, or corrosion on the surface before use.

2. When installing it, make sure that the pipe and fitting surfaces are free from dirt, debris, or any other substance that may interfere with a secure connection.

3. Use thread sealant tape or paste on both threads of mating halves before assembly to ensure a leak-proof fit when making connections between pipes with different materials such as metal and plastic/rubber hoses.

4. Tighten all bolts securely using appropriate tools such as wrenches or ratchets until desired torque is achieved; do not overtighten them otherwise you risk damaging both parts involved due to excessive strain being applied unnecessarily.

5. Regularly clean and lubricate your male camlock fittings in order to maintain their condition and prevent corrosion.

6. In order to ensure a secure and long-lasting connection between pipes or hoses, always conduct a pressure test using water or air at no more than 50 psi (3 bar) after installation.

7. If necessary, replace any worn out parts straight away in order to maintain a strong and safe connection.

Male camlock fittings are an essential part of any industrial system and are widely used for connecting pipes, hoses, and other components. With the right installation techniques and regular maintenance, these fittings can provide a secure connection that is sure to last with better performance than others. Following these tips will help ensure your male camlock fitting provides reliable service even in demanding conditions.

Common Applications for Male Camlock Fittings

They are an ideal choice for many applications due to their simple design and ease of installation. These fittings can be used in a number of industries including agriculture, construction, manufacturing, mining, plumbing and more. They are commonly used to connect pipes or hoses with different diameters or materials quickly and securely without the need for traditional threaded connections. They are also often used in applications where frequent disconnection is required such as fuel transfer systems or irrigation systems. In addition to these common industrial uses, they can also be found in everyday household items such as garden hoses and washing machines. With so many uses for male camlock fittings, it’s easy to see why they have become an essential component of any toolbox or workshop!