Inside the Innovation: A Comprehensive Guide to the Modern Camlock Factory

When we think about vital pieces of hardware that hold our world together, camlocks, also known as cam and groove couplings, might not immediately come to mind. However, these ingenious components are crucial to many industries, from oil and gas to pharmaceuticals and food & beverage production. Our focus in this comprehensive guide is to delve into the heart of their production—the modern camlock factory.

The Evolution of the Camlock Factory

Since their invention in the 1910s, camlocks have gone through significant evolutionary phases that have mirrored the changes in the manufacturing industry as a whole. Early factories were manually operated, with each camlock painstakingly assembled by hand. However, as technology progressed, so did the methods of camlock production.

From Manual to Mechanized

The advent of mechanization in the 20th century led to the gradual replacement of manual labor with machinery in camlock factories. This change increased the volume of production and improved the uniformity of products. With mechanization, camlock factories could now meet the growing demand for these versatile couplings.

Automation: The Game Changer

As we advanced into the 21st century, automation technology brought about a monumental shift in camlock production. Automation replaced redundant manual tasks with robotic equipment, which further boosted efficiency, precision, and safety. Today, it’s hard to imagine a camlock factory without the benefits of automation.

The Heart of Production: Modern Camlock Factory

A modern camlock factory is a marvel of industrial engineering, comprising various specialized departments working in unison to produce high-quality camlocks. These departments include production, quality control, research and development (R&D), and more.

Production Department

The production department is the heart of the factory, responsible for the core operations involved in manufacturing camlocks. Modern machinery and automation systems are utilized to streamline the production process, improving efficiency and reducing the risk of human error.

Quality Control Department

Quality is paramount in camlock production. Hence, each camlock passes through a rigorous quality control process. The quality control department uses advanced testing equipment to ensure that every camlock adheres to the strictest quality standards.

Research & Development Department

Innovation is at the core of the camlock industry. The R&D department is committed to continually improving and innovating the products and processes of the factory. They research new materials, design improvements, and manufacturing techniques, ensuring the company stays at the forefront of the industry.

Understanding the Camlock Production Process

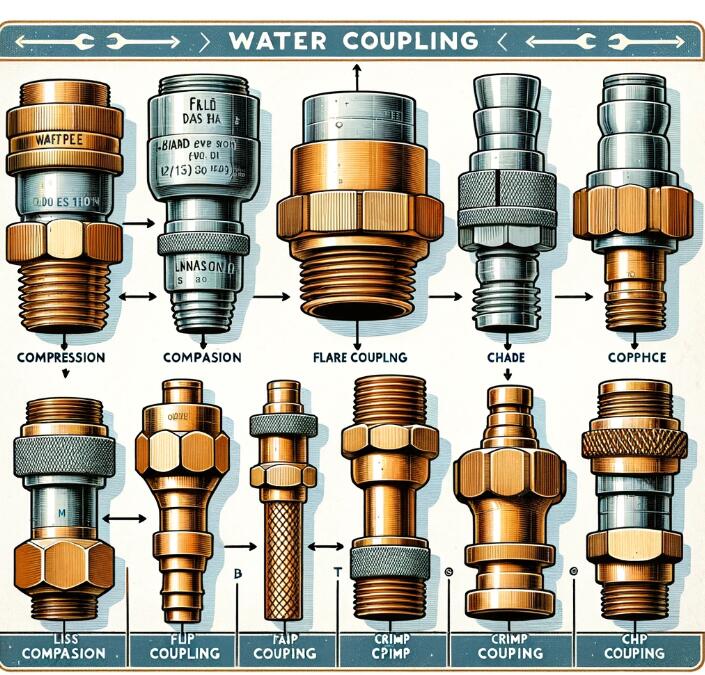

The journey of a camlock from raw material to finished product is a fascinating one. It involves several stages, each crucial to the quality and functionality of the final product. The process generally involves material selection, machining, assembly, quality control, and packaging.

Material Selection

The first step in the production process is selecting the right materials. The most common materials used in camlock production include stainless steel, aluminum, and polypropylene, each chosen for its specific properties to suit different application needs.

Machining

Once the material is chosen, it’s shaped into the necessary components of a camlock using sophisticated machining equipment. These components include the cam levers, locking arms, and body of the coupling.

Assembly

The individual components are then assembled to create the final camlock coupling. This process, while automated in most modern factories, still requires a keen eye for detail to ensure each part fits together perfectly.

Quality Control

After assembly, each camlock is thoroughly tested to ensure it meets all necessary quality standards. This involves pressure testing, visual inspections, and dimensional checks, among other tests. Only after passing all these checks is the camlock deemed ready for the market.

Packaging

The final stage is packaging the finished camlocks. They are carefully packed into boxes and pallets, ready for shipment to customers around the world.

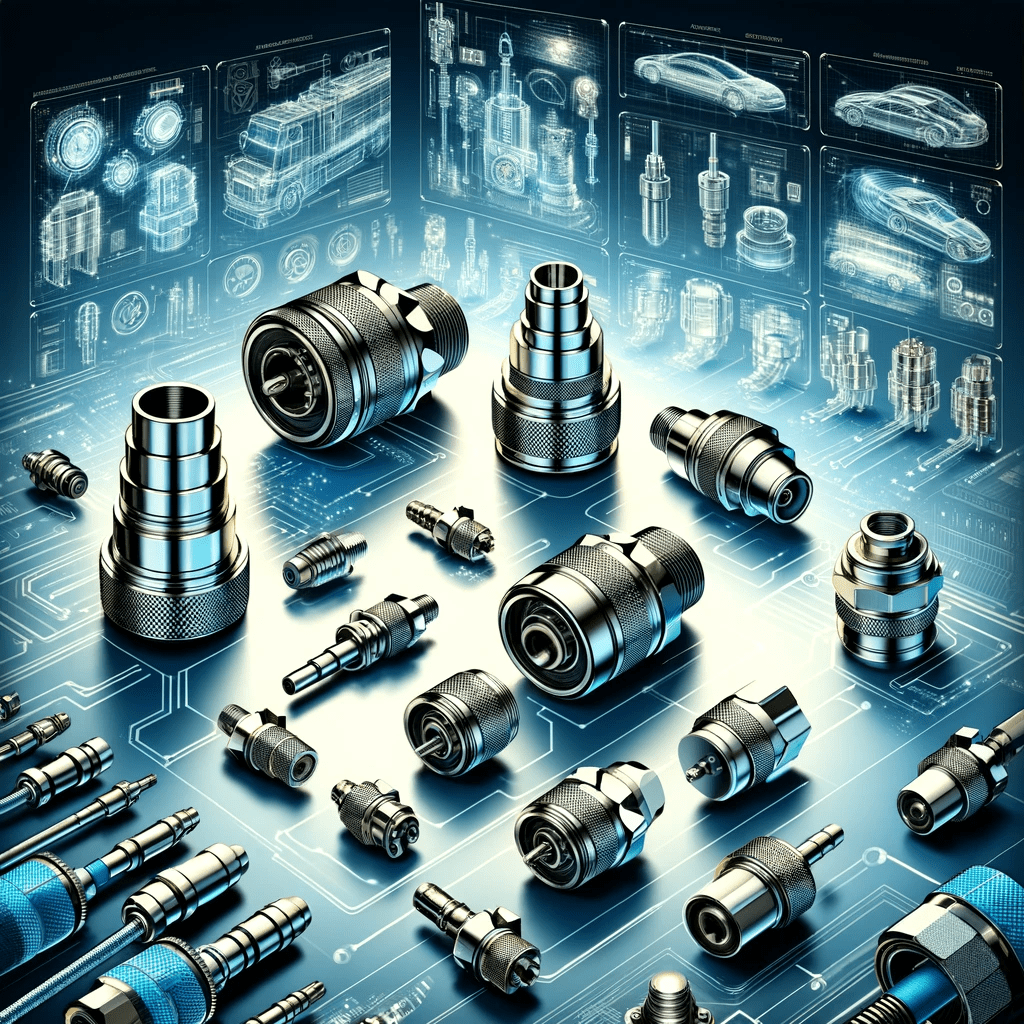

Technological Advancements in Camlock Factories

The impact of technology on camlock factories cannot be overstated. Technological advancements have helped to significantly streamline production processes, improve product quality, and enhance efficiency. Here, we delve into some key technological trends shaping the camlock industry today.

Automation and Robotics

The introduction of automation and robotics into the production process has been a game-changer for the camlock industry. Automated machines carry out repetitive tasks with incredible speed and accuracy, thereby increasing efficiency and reducing human error. Robotic arms, for instance, are often used for assembly tasks, ensuring a level of precision that would be difficult to achieve manually.

Computer-Aided Design (CAD) and Manufacturing (CAM)

CAD and CAM technologies have revolutionized the way camlocks are designed and produced. With CAD software, engineers can create and test designs virtually before they’re produced, reducing the need for physical prototypes. Similarly, CAM technology allows for precise control of machinery, leading to increased accuracy in the production process.

Internet of Things (IoT)

IoT is another significant technological trend impacting the camlock industry. By connecting machinery and systems within the factory, IoT allows for real-time monitoring of production processes. This helps in predicting and preventing equipment failures, improving maintenance routines, and ultimately increasing overall factory efficiency.

Environmental Considerations in Camlock Production

As with any industry, the manufacturing of camlocks has an environmental impact, primarily due to energy consumption and waste generation. Today, camlock factories are taking steps to mitigate these impacts and move towards more sustainable practices.

Energy Efficiency

Modern camlock factories are focusing on energy efficiency to reduce their environmental footprint. This includes the use of energy-efficient machinery and lighting, as well as practices like power factor correction to reduce energy waste.

Waste Management

Effective waste management is another crucial aspect of sustainability in camlock factories. This includes reducing waste generation, recycling wherever possible, and proper disposal of non-recyclable waste. Some factories are even using scrap metal from the production process as raw material, a practice known as closed-loop recycling.

Future Trends: The Next Generation of Camlock Factories

As we look to the future, several trends are likely to shape the next generation of camlock factories. These include increased automation, the adoption of Industry 4.0, and a greater focus on sustainability.

Increased Automation

While automation is already prevalent in camlock factories, its role is set to increase even further in the coming years. With advancements in artificial intelligence and machine learning, we can expect machines to take over even more complex tasks, further boosting efficiency and productivity.

Industry 4.0

Industry 4.0, or the fourth industrial revolution, is set to bring about significant changes in the manufacturing sector. This includes the integration of cyber-physical systems, the Internet of Things, cloud computing, and cognitive computing into factories. In the context of camlock factories, this could lead to even greater levels of automation, connectivity, and data-driven decision making.

Sustainability

With increasing awareness about the environmental impacts of manufacturing, sustainability is likely to be a key focus for future camlock factories. This could involve the use of more energy-efficient machinery, increased recycling, and possibly even the incorporation of renewable energy sources into factory operations.

Camlock factories have come a long way from their humble beginnings. Today, they are marvels of modern technology, harnessing the power of automation, computer-aided design, and the Internet of Things to produce high-quality camlocks efficiently and sustainably. As we look to the future, we can expect even more exciting advancements, as the industry continues to innovate and adapt in the face of new challenges and opportunities.