Female Camlock Connector and Fitting

Overview

Female Camlock Connector and Fitting is a type of quick-connect fitting that allows for easy connection and disconnection of hoses or pipes. It is designed with a female cam lever, which locks into place when the handle is turned clockwise. This makes it possible to quickly connect and disconnect fluid lines without having to use traditional threaded fittings. They are available in several sizes, materials, and configurations to meet the needs of various applications such as industrial liquids transfer systems, water treatment plants, chemical processing plants, firefighting equipment, petrochemical industries etc. The connector’s design ensures leak-proof connections between pipes or hoses even at high pressure levels. Additionally, they come with superior corrosion resistance due to their stainless steel construction which further increases their longevity and reliability over time.

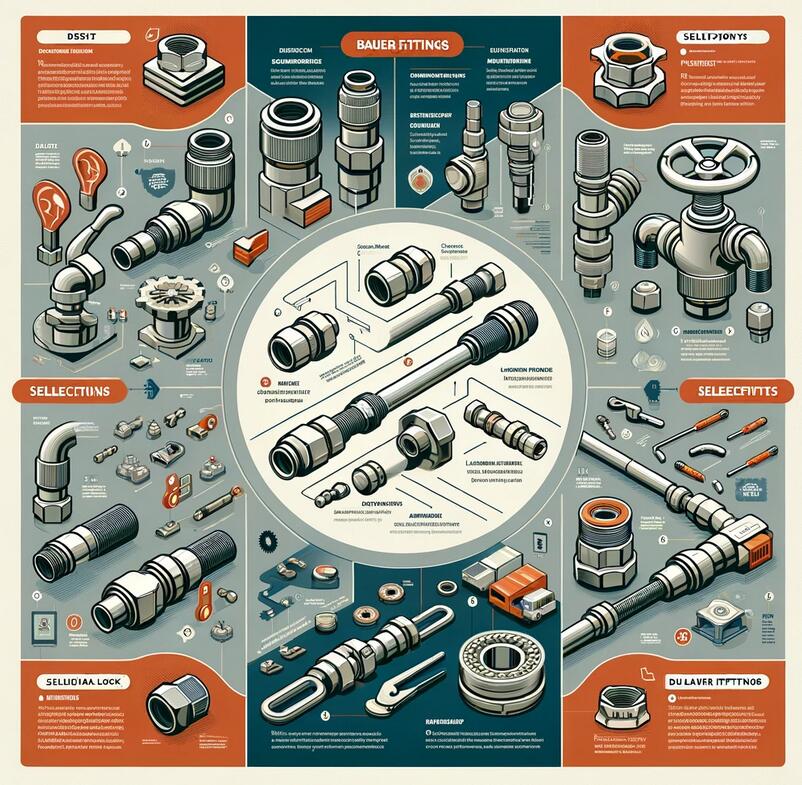

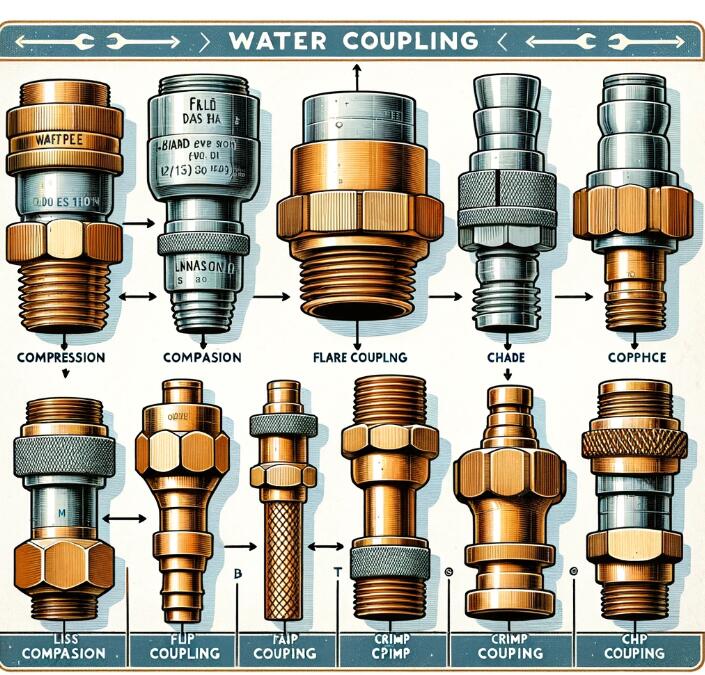

Types

Female Camlock Connectors and Fittings come in a variety of sizes, materials, and configurations depending on the application. There are four main types available – Type A (hose shank), Type B (pipe thread or cam adapter), Type C (threaded elbow) and Type D (reducing). Each type is designed to meet specific requirements for connecting hoses or pipes for transferring fluids. For instance, Type A connectors are used when attaching a hose to another hose, while type B connectors can be used with threaded pipe fittings. Similarly, type C connectors allow connection between two different sized pipes while type D fittings reduce the size of one end of a pipe fitting. They provide leak-proof connections even at high pressure levels due to their stainless steel construction which also gives them superior corrosion resistance over time.

How to Install

1. Confirm the size of the Female Camlock Connector to ensure it fits your piping system properly.

2. Clean out any dirt or debris from both parts of the fitting with a pipe brush and rag, if necessary.

3. Slide in one end of the connector into its mating part, ensuring that they are orientated correctly for proper alignment when connected.

4. Insert an O-ring seal into one side (if required) and then slide it further until it is flush against its opposite surface before securing with a locking ring or clamping collar if applicable on both ends..

5. Turn the lever clockwise on either side to lock them together securely and tighten all bolts/nuts used in connection points as required by manufacturer’s instructions for extra security..

6. Test for leaks via pressure testing or dye checking methods to check for tightness throughout connections after installation is complete..

Female Camlock Connector and Fitting can be a great alternative to traditional threaded fittings due to their ease of installation and reliable connections. With the right selection, they provide not only a secure connection but also lasting performance and corrosion resistance. Furthermore, they come in multiple sizes, materials, and configurations so that you can find the right

Maintenance Tips

To ensure the longevity and reliability of Female Camlock Connectors and Fittings, proper care and maintenance is essential. Regularly inspect the fittings for signs of wear and tear such as cracks, leaks or any other damage. If any damage is found, replace the fitting immediately. Additionally, you should also clean the connectors regularly to remove any dirt or debris which could cause problems in the long run. Finally, regularly lubricate all connections on a monthly basis to ensure they are tight and sealed properly at all times.

By following these maintenance tips, you can ensure your Female Camlock Connectors and Fittings remain reliable and secure throughout their lifespan. With proper care and maintenance, you can enjoy the convenience and reliability these fittings provide for many years.

Female Camlock Connectors and Fittings are a great alternative to traditional threaded fittings due to their ease of installation and secure connections. They come in various sizes, materials, and configurations to cater for different needs. Furthermore, they provide superior corrosion resistance and are ideal for high-pressure applications. However, proper care and maintenance is necessary to ensure their longevity, reliability and performance. With the right selection, they can be a great long-term solution for all your fluid transfer needs.